Part21J design and Part21G production

At Gama Aviation, we provide expert Part 21J design and Part 21G production services from our locations in Bournemouth and Staverton, UK. With years of experience in aircraft design and production, we offer tailored solutions to meet a wide range of aviation requirements, ensuring the highest standards of safety, compliance, and efficiency.

Part 21J Design Services

As a fully accredited Part 21J design organisation, Gama Aviation offers comprehensive design services that cover modifications, repairs, and upgrades for a wide variety of aircraft types. Our team of highly skilled engineers and designers works closely with clients to develop innovative, cost-effective solutions that enhance aircraft performance and extend operational life. Whether you need modifications to avionics, interiors, or structures, we provide fully certified design solutions that comply with EASA and UK CAA regulations.

Part 21G Production Services

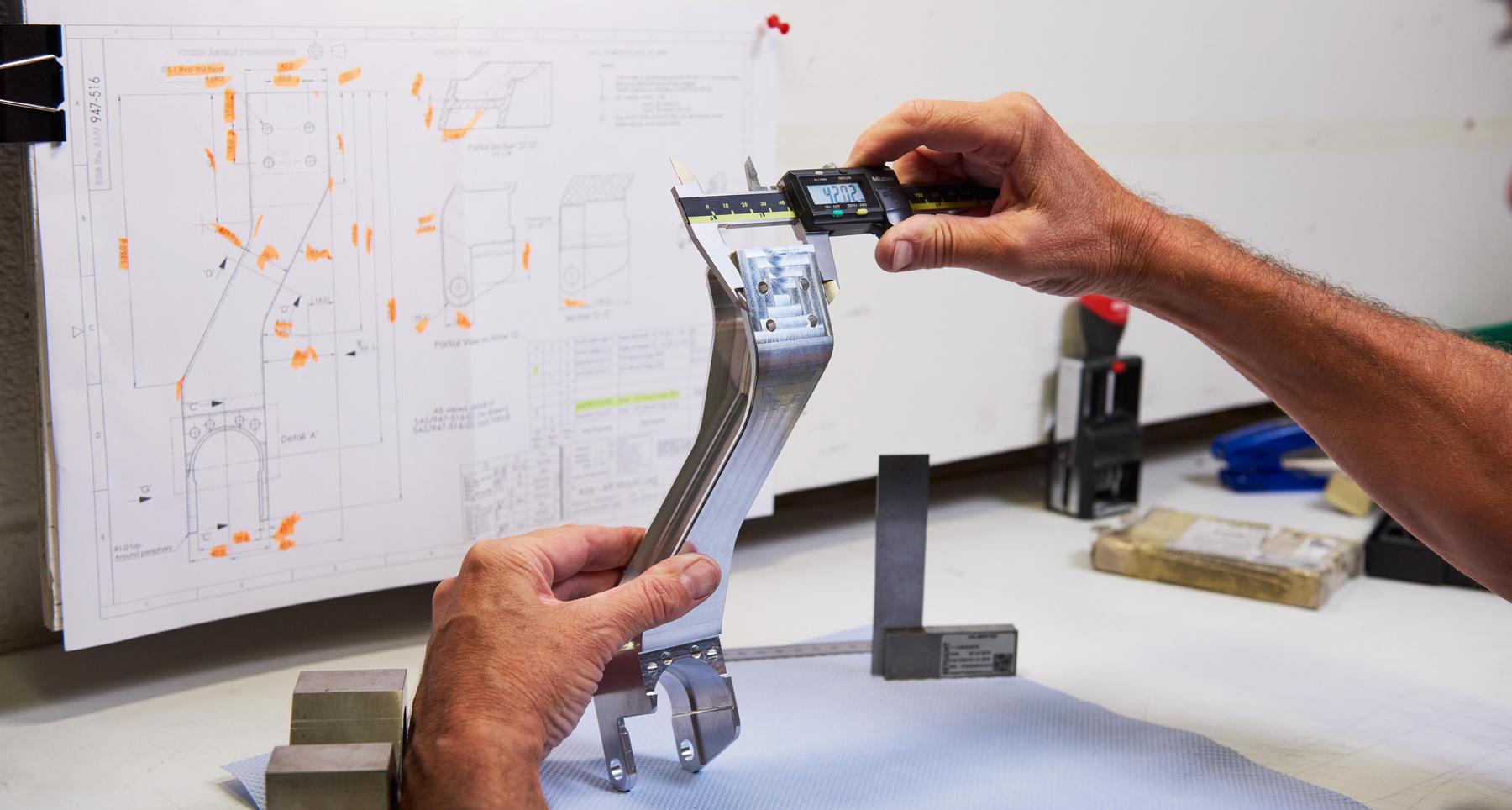

Our Part 21G production approval enables us to manufacture and certify aircraft parts at our state-of-the-art facilities in Bournemouth and Staverton. From bespoke components to full assemblies, our production team ensures every part meets rigorous quality standards and is delivered on time to support your operational needs. Our production capabilities include everything from prototype development to full-scale production, with a focus on precision and reliability.

The benefits of workign with us

- check_circle Experience and Expertise: Decades of experience in aviation design and production, providing trusted solutions for a wide range of aircraft.

- check_circle Compliance withUK CAA Regulations: Ensuring your aircraft is safe, compliant, and airworthy.

- check_circle Tailored Solutions: Bespoke design and production services to meet your specific requirements.

- check_circle End-to-End Services: From initial design concepts to final production, we handle the entire process, ensuring a seamless experience.

- check_circle Highly Skilled Team: Expert engineers, designers, and production staff delivering innovative and reliable solutions.

- check_circle Fast Turnaround Times: Efficient processes to minimize downtime and maximize aircraft availability.

phoneArrange a call

Whether you need design modifications or bespoke parts production, Gama Aviation’s Part 21J and Part 21G capabilities in the UK ensure your aviation project is completed to the highest standards, keeping you flying safely and efficiently.If you would like more information on our Special Mission capabilities please click on the links below:

- check_circle Military mission systems

- check_circle Police & law enforcement mission systems

- check_circle Air Ambulance mission systems

Mechanical design & rapid prototyping

Our UK CAA Part 21J team are well versed in all aspects of the mechanical design process particularly in the field of rapid prototyping and integrated CAD simulation. This area is of particular value in the design process during the final stages of determining the final specifications / requirement definition. This can, depending on the modification, remove the need for costly full cabin mock-ups and models which inherently have a low level of utility after this phase.

- 3D Design for Fabrication, machining & composites.

- Stress calculations, Damage Tolerance & Fatigue Analysis

- Rapid prototyping (3D printing)

- Integrated CAD simulation (Finite Element Analysis)

Electrical design including avionics and mission requirement modifications / upgrades

One of the largest elements of our work with clients is in updating or modifying electrical systems that are fundamental to either the airworthiness of the aircraft or enhance their relevance to changing mission criteria. In all cases our focus is how to cost effectively deliver the client’s mission but also protect / future proof the platform for ‘mission creep’ or predicted changes in air traffic control such as ADS-B Out or TCAS.

Of particular note are the changes in airborne connectivity and how aircraft are being equipped for higher speed data links. This is usually seen to be the domain of applications such as in-flight Wifi for the business aviation sector however it has greater applicability within the Air Ambulance community, with the flow of secure patient data between hospitals, paramedics, land and air services (you can find more on connectivity services here)

Typically the team will deliver the following systems:

- Avionic Cockpit Upgrades

- Flight Management Systems

- Camera Mounts

- Satcom Upgrades and data connectivity

- Flight Data Recorders

- Transponders, TAWS, TCAS

- Radar

- NAV-COMM

- Rad Alt

Mission systems and aircraft role enhancement

We possesses industry leading expertise in the development, integration and support of Intelligence, Surveillance and Reconnaissance (ISR) solutions (for more details see Mission Systems). Our specialist staff offer a full spectrum of design and production services from project inception through to delivery. Typical mission enhancement projects include:

- Integrated Systems

- Mission Consoles

- Tactical Radios

- E/O and I/R Optics

- Mission Computers

- Mapping Solutions

- NVG

- Flight Data Recorders

Interior design & modifications

From high-end business jet requirements to mission modifications for Air Ambulance, we provide a range of services for clients which include the full re-role of aircraft to refurbishments of seating.

- Interior upgrades (carpet, seating, cabinetry, upholstery, etc.)

- Air Ambulance modifications (cabinets, patient loading systems, storage systems, etc.

- Child seating systems

- Rapid prototyping

Refurbishment projects. Renewing the life of 37 year old Beechcraft King Air 200 seats

The solution to every problem doesn’t always require a new replacement.

After analysis of the cost benefit of new vs old the Part 21J Design team have just completed a B200 King Air Seat refurbishment project. The 37-year-old seats that had seen better days were stripped down to the frame, inspected, repaired and then rebuilt to the customers specification while addressing marginal weight saving gains.

The top images show the previous state of the seats showing everyone of their 37 years of service. Those below show the completed seat prior to being refitted back into the airframe.

UK CAA Part 21 G production services

In addition to our Part 21J design services we also provide P145 and P21G production offering a complete end-to-end solution within a single organisation. This assists our clients as they have one project management interface with full accountability from design, to production to the installation of the modification. Post installation, our clients also benefit from a global support structure that is ready and able to ensure your availability if maintained.

Part 21G services are as follows:

- Metal Fabrication

- Machined Parts

- Manufacture of Mechanical Assemblies

- Metal treatments

- Composite manufacture

- Composite Repairs

- Production of Cable Harnesses

- Manufacture of Electrical Assemblies

- Building SUB Assemblies

- Kitting

- Interior Panels

- Interior Trim

- EASA Form 1 Release

Part 21 J aviation design STC's for purchase

New Part 21 J design STC applications are being submitted on a regular basis, please contact the design office for further information. Our capability also includes the approval of existing avionics equipment and installations on aircraft.

For more information please arrange a call with one of our team.

phoneArrange a call

Contact us

Part 21J aviation design & Part 21 G production Contact Details

Location coverage

Bournemouth International Airport (EGHH)

Our Bournemouth International Airport facility, a hangar and office facility of over 135,000 sq ft provides an extraordinary space which we aim to turn into one of Europe’s flagship business aviation facilities.

Read moreGloucester Airport (Staverton)

Gloucester Airport is the home of our Leonardo AW169 and AW139 maintenance capability as well as the centre of excellence for AW169 air ambulance interiors.

Read more