Mission Systems Design for Police application

The Police Mission System Design team are adept in taking a CONOPS challenge and designing a full, law enforcement, ISR architecture that can be deployed on fixed wing types (such as the King Air, Vulcanair, Islander, DA-20) or rotary types (such as the Airbus H145, H135, AW169 or Bell 429)

At the core of the Police Mission System Design capability is our ISO9001, UK CAA Part 21 J & G, approved organisation that undertakes a broad range of aircraft design and production services to supply avionic, structural design and certification to a wide variety of defence, law enforcement and survey clients. The team has worked with a large cross section of customers on a wide variety of applications which include:

- Design and architecture of Police ISR mission systems

- Re-role of aircraft to accommodate new Police mission systems

- Testing and evaluation of Police Mission Systems Design components

- Updating cockpit and rear operator interfaces

- Other bespoke projects as per the CONOPS requirement

Police modifications

Our extensive range of police and law enforcement modifications for application on border monitoring, missing persons, police intelligence, crowd observation, passive standoff, road & traffic operations and counter-terrorist operations include:

- Augmented Reality Mapping Systems (ARS)

- Customer Specific Systems

- Digital Audio Communication System (DACS)

- Downlink & Uplink Systems

- Electro-Optical & Infrared Sensors (EO/IR)

- External Pods

- LOPA Changes

- Light Detection and Ranging (LiDAR)

- Mission Displays & Monitors

- Mission Seating

- Operator Workstations

- Operator Consoles

- Night vision Imaging Systems (NVIS)

- NVIS Lighting

- Retractable Camera Installations

- Satellite Communication Systems (SATCOM)

- Specialist Antennas

- Surveillance Role Fits

- Tactical Radios (TETRA)

- Video / Mission Recorders

- Video Management Systems (VMS)

Our process

Too often we hear from those who have commissioned aviation mission system design projects only to find that a simple Minor Change has turned into a monster project.

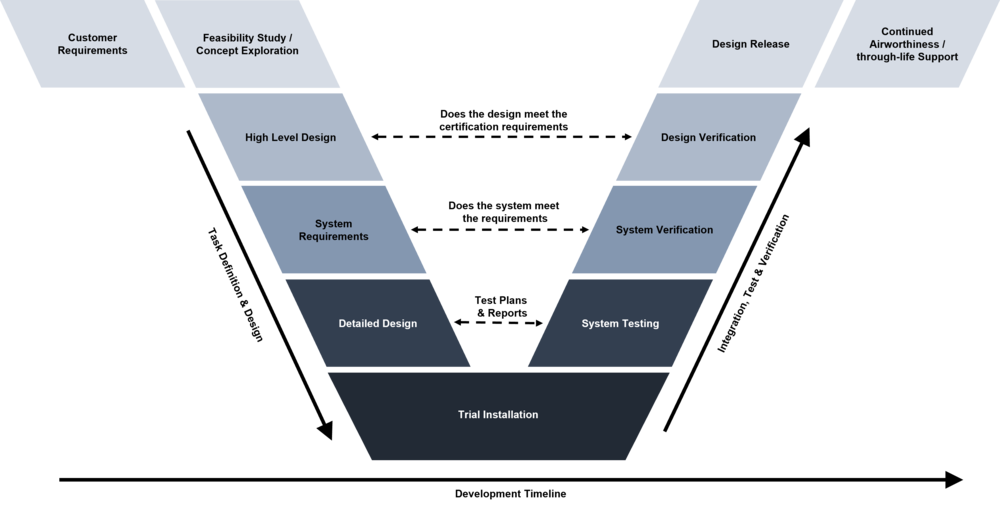

We are firmly of the belief that engaging in open and honest discussions with all stakeholders helps us to set clear expectations and provide expert guidance from the start, avoiding the problem of scope creep. To assure a timely, planned and controlled process we aim to assist our customers in making the correct design decisions using our established methodology, whilst ensuring compliance with all regulatory, statutory and legal requirements. Our design process is defined by gateways as illustrated below.

- Project Management support

Regardless of the size and complexity of the project, our Project Management Office (PMO) will be on hand to manage the entire process from your initial briefing through certification to embodiment. The team has a wealth of experience in designing Minor & Major Changes for Police, Law Enforcement, Border Control and National Security clients and their bespoke Mission System requirements. - Minor or Major change

All modifications are classified as either Minor or Major Changes, both of which have different development paths, risks and associated timelines. One of our first steps is to check to see if one of our many existing ‘off-the-shelf’ designs are suitable, saving the client both time and money. If this is not the case, we then proceed to classify the Change as Minor or Major. - Inputs

Working with the Pilots, Rear Operators, and the Project Team we will with our Design Team collaborate with OEM’s to identify suitable equipment for the concept of operations (CONOPS). The design team then consider the ergonomic, anthropometric, and operational suitability aspects and present them to the customer at key milestones such as Preliminary Design Review (PDR) & Critical Design Review (CDR). - Outputs

Building from the use cases and CONOPS requirement and our initial design concepts, we employ a wide variety of techniques to produce prototypes & illustrations for customer validation. These include 3D renders, full-scale ‘mock-ups’ and ‘in-house’ 3D printing to name a few. These will be presented to the key stakeholders at the earliest opportunity to gather feedback and approval prior to manufacture. The creation of prototypes also allows the Rear Operators to provide valuable input and visualise how the design change will affect their working environment. - Internal reviews

We continuously review the design process and evaluate all decisions being made to highlight any challenges that may present themselves during the compliance and verification stage. This includes weight and balance, electrical load, interior layout and operational performance.

We see our job as a partner to the Project Team, helping the Project Team to navigate the design process to ensure that the solution meets the CONOPS requirements and provides a sustainable solution for Police, Law Enforcement, Border Control and National Security agencies.

Interior Design

From complete mission interior changes to a NVIS lighting upgrades we have it covered. We also design and manufacture bespoke mission architectures, rear operator consoles to reduce rear operator fatigue and stowages to meet our clients’ CONOPS requirements.

Typical Cabin Interior projects undertaken by our Design & Production Team include:

- Cabin Lighting

- Cabin Wi-Fi

- Medical flooring

- Emergency Lighting

- Equipment Racks

- LED Lighting Upgrades

- LOPA Changes

- Monitors

- Non-Textile Flooring (NTF)

- Overhead Lockers

- Placards

- Power Inverters

- Restraints

- Seat Retrimming

- Stowages

- Tables

- Thermal Trim and Insulation

- USB Charging Points

Mechanical Design

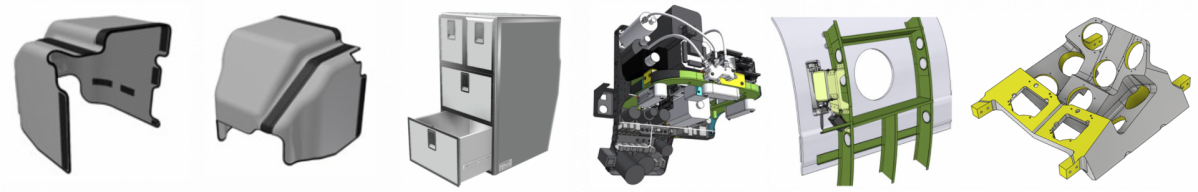

Using the latest 3D Computer Aided Design (CAD) software, our team are ready to support you in all of your mechanical design needs. Modifications and repairs typically require mechanical design. The team are experienced in all aspects from technical survey, initial hand calculations, through detail design development to creation of production drawings and computer aided manufacturing data.

Examples of projects and additional services covered by our Mechanical Team include:

- 3D Scanning

- Adapter Plates

- Antenna Installations

- Anti-Vibration Mounts

- Blanking Plates

- Bulkhead Penetrations

- Chart Holders

- Circuit Breaker Panels

- Detail, Assembly & Installation Drawings

- Doublers (Internal & External)

- Empennage Changes & Repairs

- Equipment Mounts

- Equipment Racks & Trays

- Fairings

- Flooring

- Fuselage Changes & Repairs

- Ground Support Equipment

- Hard Points

- Instrument Panels

- Mock-Ups

- Monuments & Stowages

- Rapid Prototyping (3D Printing)

- Structural Repairs

- Tie Rods

- Wing Changes & Repairs

Electrical Design

Using the latest Electrical Computer Aided Design (ECAD) software, our team are ready to support you in all of your electrical design needs. Modifications and repairs with electrical aspects will involve numerous assessments, such as power distribution, electrical load analysis and electromagnetic compatibility.

Typical projects undertaken by our Electrical Team include:

- Annunciator Panels

- Annunciators

- ARINC Signal Converters

- Avionic Backup Batteries

- Battery Upgrades

- Circuit Breakers

- Communication Ports (RJ45, RS-232)

- Electric Start Systems

- Generators

- Ground Use Batteries

- Instrument Panel Lighting

- Instrument Panel Plugs

- Inverters

- LED Lighting (Internal & External)

- NVIS Lighting

- Passenger Service Units

- Power Outlets

- Redundant Wiring Removal

- Switch Guards

- Switches

- USB Charging Sockets

- Warning Lights

- Wiring Diagrams

- Wiring Repairs

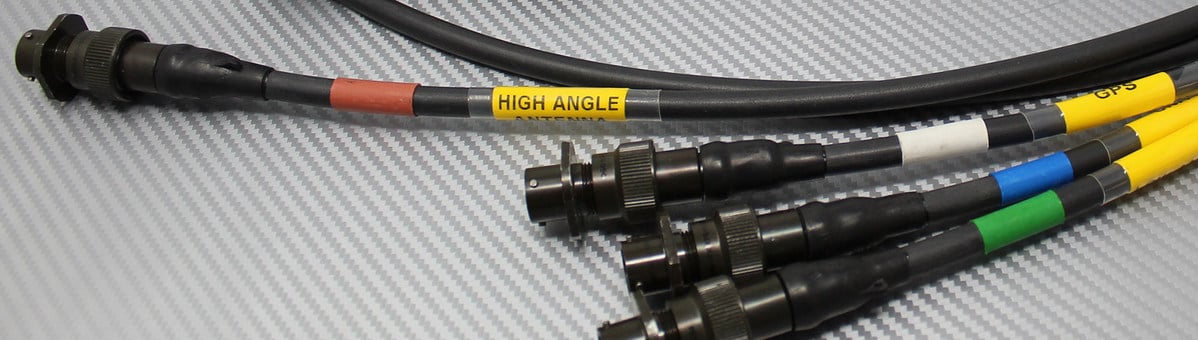

Manufacturing & Assembly

Our assembly shop floor has been laid out to ensure that the creation and production of parts follows a lean process. We have the capability to assemble components of any weight and size both mechanical and electrical. All assembled parts are fully inspected and released with either a Form One or C of C.

Typical assembly work undertaken by us includes:

- CAA approved welding

- Capability to assemble components of any size.

- Certificate of Conformity

- Composite Assemblies

- Crimping

- Electrical Assemblies

- Form One Release

- Fully configurable assembly area

- Kits of Parts with Release Certification

- Mechanical Assemblies

- Mission System Consoles

- Painting

- Surface treatments

- Threaded inserts

- Wet bonded assemblies

- Wiring Looms & Harnesses

Mission Systems Design Certification

As an approved design and production organisation certification is at the heart of everything we do here at Gama. We are experienced in producing both Major & Minor Changes and Repairs that are either approved or accepted by the various National Aviation Authorities (NAA’s) across the world.

With over 1700 Minor Changes & Repairs and 70+ STC’s within our portfolio we often have an off-the-shelf design solution to fit your particular needs.

However, we also realise that not every aircraft is the same and every project is different, if we don’t have a pre-existing design we have the capability and approvals to produce a new Change or Repair to support your particular aircraft and operation.

Our core certification activity includes:

- Minor Changes created in-house

- Minor Repairs created in-house

- Major Changes & STC’s

- Validations of Minor Changes, Repairs & STC’s

- Experienced in working with the vast majority of the world’s NAA’s

- Experienced in both Civil & Military certification

We work closely with the following Authorities:

Supported aircraft

Airbus H145

The Airbus H145 helicopter is our aircraft of choice for HEMS operations. Find out more here.

Read moreBeechcraft King Air 200 series

We offer operational & maintenance expertise across the Beechcraft King Air 200 series of aircraft.

Read moreBeechcraft King Air 300 series

We offer availability and expertise across the BAE Hawker series of aircraft, including charter services, maintenance approval and capabilities and we have extensive management experience, having owned and operated BAE Hawker aircraft ourselves and for our clients.

Read moreBritten Norman BN2-T Islander

The Britten Norman Islander BN-2T is used within both a civilian and Special Mission context being able to accommodate various interior fitments from executive to up to three stretchers for Air Ambulance operations.

Read moreLocations

Bournemouth International Airport (EGHH)

Our Bournemouth International Airport facility, a hangar and office facility of over 135,000 sq ft provides an extraordinary space which we aim to turn into one of Europe’s flagship business aviation facilities.

Read moreGroup Headquarters, 25 Templer Avenue, Farnborough.

25 Templer Avenue, Farnborough is home to our Group headquarters and is the nerve centre for the European Air division. With excellent access to the facilities at the airport.

Read more